Quick OVERVIEW of the knowledge about Ball Valves (Part Two)

Ball valve is mainly used in the pipeline to cut, distribute the flow and change the flow direction of the medium. It can be closed tightly by only a small torque and being rotated 90 degrees. The ball valve is most suitable for use as a switch or shut-off valve. Ball valves were produced in the 1950s. With the rapid development of science and technology, the continuous improvement of production technology and product structure, ball valve has rapidly developed into a major valve category in just 50 years.

Since ball valves typically use rubber, nylon, and Teflon as the seat seal material, their service temperature is limited by the material of the seat seal. The cut-off function of the ball valve is achieved by the ball being pressed against the valve seat under the action of the medium (floating ball valve). The valve seat seal is deformed by elastic deformation in a local area under certain contact pressure. This deformation can compensate for the manufacturing precision and surface roughness of the sphere and ensure the sealing performance of the ball valve.

Also because the seat seal of the ball valve is usually made of plastic, in the structure and performance of the ball valve, the fire resistance and fireproof of the ball valve should be considered, especially in the petroleum, chemical, metallurgical and other industries. One should pay more attention to fire protection when using ball valves in equipment and piping systems with a flammable and explosive medium.

Classification of ball valves

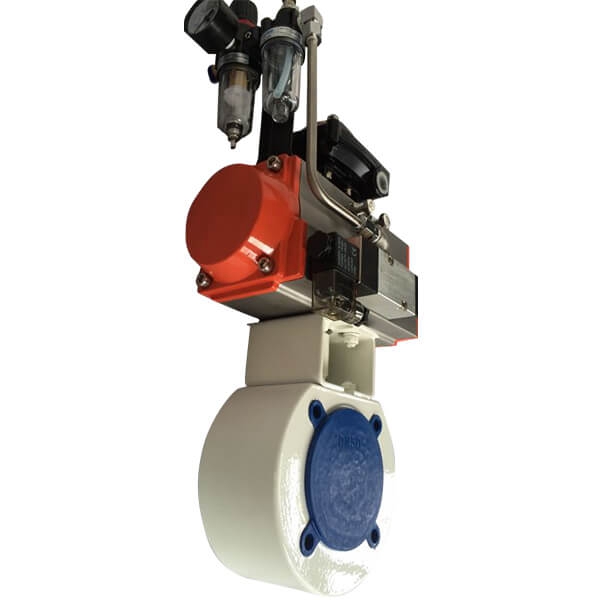

Ball valves can be divided into floating ball valve, trunnion ball valve, track ball valve, V-shaped ball valve, three-way ball valve, stainless steel ball valve, cast steel ball valve, forged steel ball valve, dust discharging ball valve, anti-sulfur ball valve, welded ball valve. In addition, according to the function and transmission form, it can be classified to air ball valve, bypass ball valve, pressure-release ball valve, drainage ball valve, or pneumatic ball valve, electric ball valve, hydraulic ball valve, pneumatic hydraulic ball valve, electric hydraulic ball valve, turbo driving ball valve.

Characteristics of ball valves

1. It has the lowest flow resistance (actually zero).

2. The ball valve will not get stuck when there is no lubricant, so it can be reliably applied to corrosive media and liquids with a low boiling point.

3. A 100% sealing performance can be achieved over a wide range of pressures and temperatures.

4. It can realize fast opening and closing. The opening and closing time of some structures is only need 0.05-0.1s. When the valve is quickly opened and closed, the operation is shock-free.

5. The ball can be automatically positioned.

6. Both sides can be sealed in high performance.

7. When fully open or closed, the sealing surface of the ball and the seat is isolated from the medium, so the medium pass through the valve at high speed does not cause erosion of the sealing surface.

8. Ball valves are compact and lightweight, can be considered as the most reasonable valve structure for low temperature media systems.

9. The valve body is symmetrical, when welded to the valve body structure, it can withstand the stress from the pipe well.

10. The closing member can withstand the high pressure difference at the time of closing.

11. Ball valves with full welded valve body can be buried directly under the ground, so that the valve internals are not eroded. The maximum service life can reach 30 years, it is the most ideal valve for oil and natural gas pipelines.